How Do General Contractors Determine Labor and Material Costs?

Learn how a general contractor Lakewood calculates labor and material costs to give project estimates. Get insights that make budgeting for your job easier.

Every construction project has a foundation—solid planning. A big part of that planning comes from understanding how a general contractor Lakewood, breaks down labor and material costs. These aren’t just numbers on a page. They shape the entire project from the ground up, influencing timelines, pricing, and results.

Getting this right from the start helps everyone stay focused, organized, and aligned. It also avoids surprises halfway through the job. For homeowners or property managers, knowing how the process works means smarter decisions, better conversations, and fewer headaches. It creates transparency in an area that can otherwise feel confusing.

What a General Contractor Lakewood Considers When Quoting Labor and Material

No single formula fits all situations. Location, crew availability, supplier pricing, and scope shape every estimate. Offering general contractor services demands accurate quotes that balance dozens of variables—especially when people and products come into play.

A detailed quote illustrates how the team will allocate time and resources during the project. Contractors should consider the job’s size, potential challenges, and time requirements. Furthermore, terrain and local permitting requirements may significantly impact costs. Begin by matching each selected material to the corresponding labor required for installation. Furthermore, ensure that every hour spent on-site is accounted for.

Understanding Labor Cost Calculations

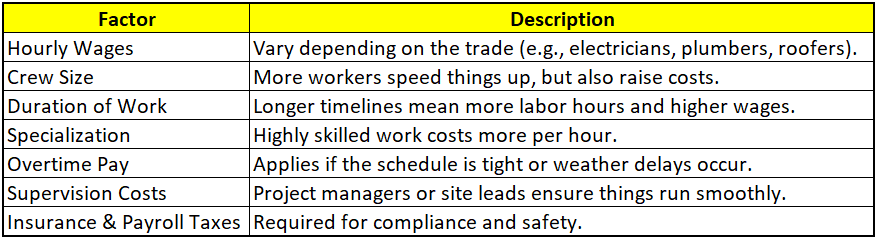

Labor is a complex part of the estimate because people are involved. It depends on time, skill level, project phases, and team structure.

To build accurate pricing for labor, professionals use the following method:

Our remodeler Lakewood, knows labor costs can shift mid-project if changes are introduced. That’s why building in accurate buffers and sticking to project milestones is so important. As labor markets tighten, costs tend to rise. Experienced contractors, therefore, plan for this and adjust their timelines accordingly. By factoring in breaks, tool use, and team coordination, we can ensure smoother execution and fewer on-site complications.

How Material Costs Are Determined

Material costs go beyond just product pricing. Logistics, waste management, and vendor reliability all shape how these costs get quoted.

Here’s how contractors typically estimate materials:

Use supplier pricing from trusted sources

Factor in bulk discounts for volume-based orders

Add delivery and freight charges

Include rental or storage fees

Account for material waste (about 5–10% buffer)

Track lead times that could affect scheduling

Pricing tends to be higher for a more complex build, such as a bathroom upgrade, due to the inclusion of custom fixtures and finishes. Materials costs, on the other hand, fluctuate often. Market conditions can fluctuate, and as a result, seasonal demand may increase. Furthermore, shortages can contribute to sudden price jumps. Contractors frequently utilize supplier networks to secure feasible pricing and guarantee timely delivery. Reliable vendors are crucial for maintaining timelines; furthermore, quality materials significantly reduce the chance of rework.

Subcontractors and Their Role in Cost Structure

General contractors rarely handle every aspect themselves. Subcontractors—licensed professionals specializing in electrical, HVAC, plumbing, and structural work—become part of the job.

When using subcontractors, contractors:

Gather and review subcontractor quotes

Schedule their availability around the main timeline

Verify licenses and compliance

Track coordination between trades to avoid downtime

Some trades must pass inspections or meet municipal guidelines, which adds another layer of time and cost to the equation. Our general contractor Lakewood, manages the scheduling puzzle, ensuring plumbing isn’t delayed because drywall was installed too soon. Coordination like this prevents extra charges and keeps the job on track while maintaining quality standards.

The Importance of Real-World Experience

Spreadsheets and estimation software help with numbers. But experience tells the bigger story. Past jobs give contractors the insight to spot red flags, prevent over-ordering, and know precisely how long tasks should take.

Some benefits of experience-led quoting include:

Avoiding overstaffing

Choosing better suppliers

Predicting weather-related delays

Budgeting more accurately for finish materials

Preventing scope creep

Our remodeler Lakewood, often uses past jobs as a template to streamline estimating future projects of similar size and complexity. Real-world experience also allows contractors to adjust on the fly. They know what materials fail under certain conditions or what steps usually cause timeline bottlenecks. Lessons learned from hundreds of job sites become second nature. That kind of foresight helps keep surprises out of the budget and boosts overall client satisfaction.

Price Markups: Why They Exist

All contractors add markups. It’s not just about profit—it keeps the business running and protects the client during unforeseen delays or material shifts.

Markups cover:

Office and admin costs

Insurance

Site inspections

Warranty coverage

Equipment maintenance

Depending on job size and complexity, markups typically range from 10% to 30%. Without this, there’s little room to adjust if something changes unexpectedly, like supplier costs rising overnight.

These markups also serve as a risk buffer. If a subcontractor cancels or a material shipment is delayed, the project doesn’t halt. Instead, the contractor can move forward with alternatives. This flexibility reduces downtime and eliminates the need to renegotiate mid-project. It’s a built-in safety net for everyone involved.

How Detailed Estimates Prevent Future Problems

Estimates that lack detail create confusion later. Strong estimates offer complete transparency about costs, scheduling, expectations, and responsibilities.

Key features of a well-prepared estimate:

Itemized breakdown of labor and materials

Timelines for every primary project phase

Clarification of what is and isn’t included

Clear payment schedule and terms

Instructions on how changes will be handled

When offered by a qualified general contractor Lakewood, this level of clarity helps projects run smoothly, with fewer delays and better results. With well-organized estimates, both clients and contractors avoid back-and-forth debates mid-project. Each stage is clearly defined, and every dollar has a purpose. Questions are answered before they come up. This level of detail builds mutual understanding, reduces project risk, and helps all stakeholders move forward confidently.

Final Takeaway

Indeed, a reasonable estimate goes beyond mere numbers; it fundamentally hinges on trust. Clients desire to feel assured about their hiring choices and the value of their investment. Contractors who build honest, experience-based estimates help create smooth projects and foster long-lasting working relationships.

When people search for a remodeler for luxury bathroom near me, understanding how costs are calculated helps them make better, more informed decisions before the first hammer swings. Villanueva H Construction Inc. commits to providing reliable, experience-backed general contractor services. From the first quote to the final walkthrough, we build every step on clarity, communication, and commitment.